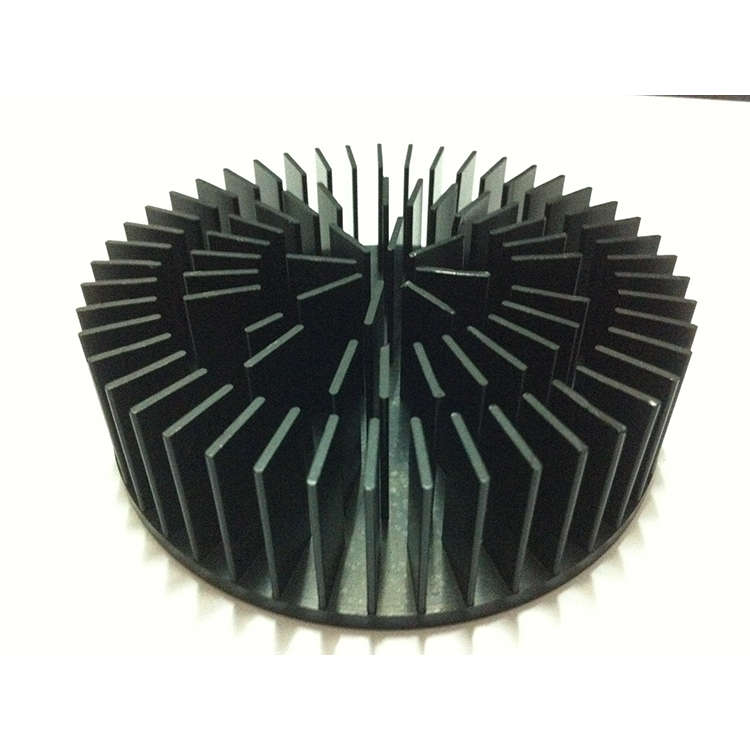

Extruded Aluminum Sunflower Heatsink

1) Alloy6061,6063,6063B,6060,6005,6N01

2) Alloy chemical element profile

Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti |

6063 | 0.2-0.6 | 045-0.9 | <0.35 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

6061 | 0.4-0.8 | 0.8-1.2 | <0.7 | 0.15-0.4 | 0.15 | 0.25 | 0.04-0.35 | <0.05 |

6063B | 0.2-0.6 | 045-0.9 | <0.35 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

6060 | 0.3-0.6 | 0.35-0.6 | 0.1 | 0.1 | <0.1 | 0.15 | 0.05 | 0.1 |

6005 | 0.6-0.9 | 0.4-0.6 | 0.35 | 0.1 | 0.1 | <0.1 | <0.1 | <0.1 |

6N01 | 0.4-0.9 | 0.4-0.8 | <0.35 | <0.35 | <0.5 | <0.25 | <0.3 | <0.1 |

3) TemperT3-T8

4) Surface Treatment

1.drilling 2.tapping 3.punching 4.wiredrawing 5.sand blasting 6.milling 7.polish

8.cutting 9.straightener 10.anodized

4)Anodized Colour:silver, red, champagne, black, blue, bronze and so on.

5)Machining procedure:die casting ,make mould,extrusion ,CNC (milling finish),cutting,anodized